PULVERIZERSIFP and IRP Series

By using the latest technologically advanced materials, such as special extra-strength HARDOX® steel alloys, Indeco pulverizers are specifically designed to withstand high levels of pressure, wear and abrasion, and prolonged use regardless of jobsite conditions.

IFP and IRP Series

By using the latest technologically advanced materials, such as special extra-strength HARDOX® steel alloys, Indeco pulverizers are specifically designed to withstand high levels of pressure, wear and abrasion, and prolonged use regardless of jobsite conditions.

FEATURES

Exploiting the best in Indeco's advanced technological know how, the Indeco IFP fixed and IRP rotating pulverizers were designed and created following the top quality guidelines already used in manufacturing our famous hydraulic breakers. By using the latest technologically advanced materials, such as special extra-strength HARDOXŽ steel alloys, Indeco pulverizers are specifically designed to withstand high levels of pressure, wear and abrasion, and prolonged use regardless of jobsite conditions. IRP rotating pulverizers are perfect not only for the primary demolition of buildings, vertical structures, flooring, slabs and external walls. The IFP fixed versions are perfect for the secondary demolition of reinforced concrete materials and structures, and for recycling after separating the concrete from the steel rods.The unique shape of Indeco pulverizers is a design feature created specifically to reduce the variation in the force required between the start (maximum opening) and the finish (minimum opening) so as to increase efficiency and continuity, and to reduce both working times and stress transmitted to the excavator. The hydraulic system is equipped with a “regeneration valve” which enables the mobile jaw to be closed more quickly under no-load conditions, in order to apply all of the force available only when pulverising material, thus increasing productivity.

Other key features which keep Indeco pulverizers efficient in the long term: the adjustability of the distance between the cutters located inside the jaws, so that steel rods inside reinforced concrete can be cut more efficiently; the interchangeable teeth on the mobile jaw (welded onto a bolt-on plate and secured with special latches) for optimal penetration of the material being demolished.

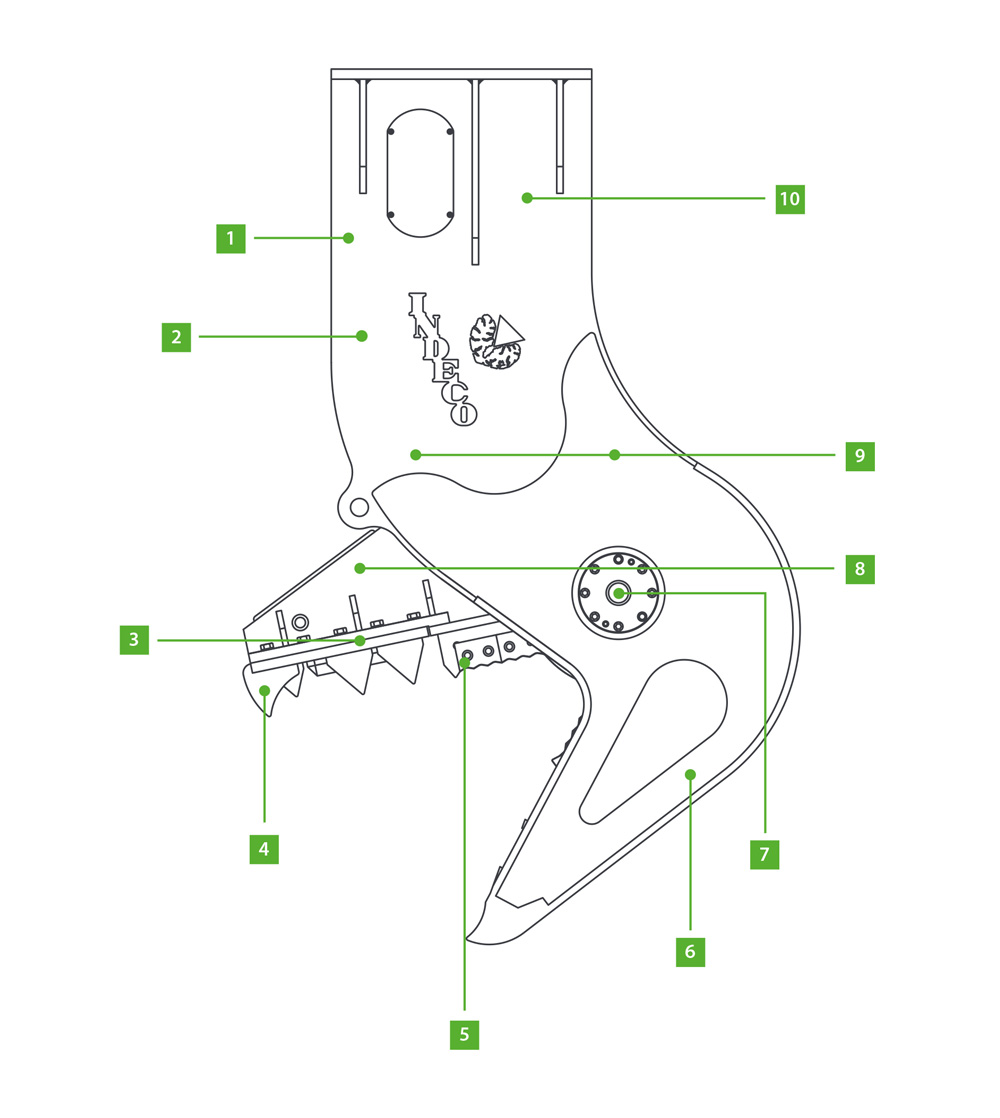

- 1 Position of hydraulic cylinder protects the rod.

- 2 Exclusive geometric design which ensures that the pulverizing force remains as constant as possible between maximum and minimum opening.

- 3 Special latches.

- 4 Interchangeable teeth mounted on a bolt-on plate with tooth sockets.

- 5 The distance between the cutters located inside the jaws can be adjusted, so that steel rods inside reinforced concrete can be cut more efficiently both sides of the interchangeable cutters can be used.

- 6 Innovative design provides better grip and improves manoeuvrability, extremely rigid structure prevents buckling.

- 7 Greasing system for better lubrication of moving mechanical parts.

- 8 Wide opening between the jaws.

- 9 Frame and jaws made with HARDOX©.

- 10 "Regeneration valve" which enables the movable jaw to be closed more quickly under no-load conditions.

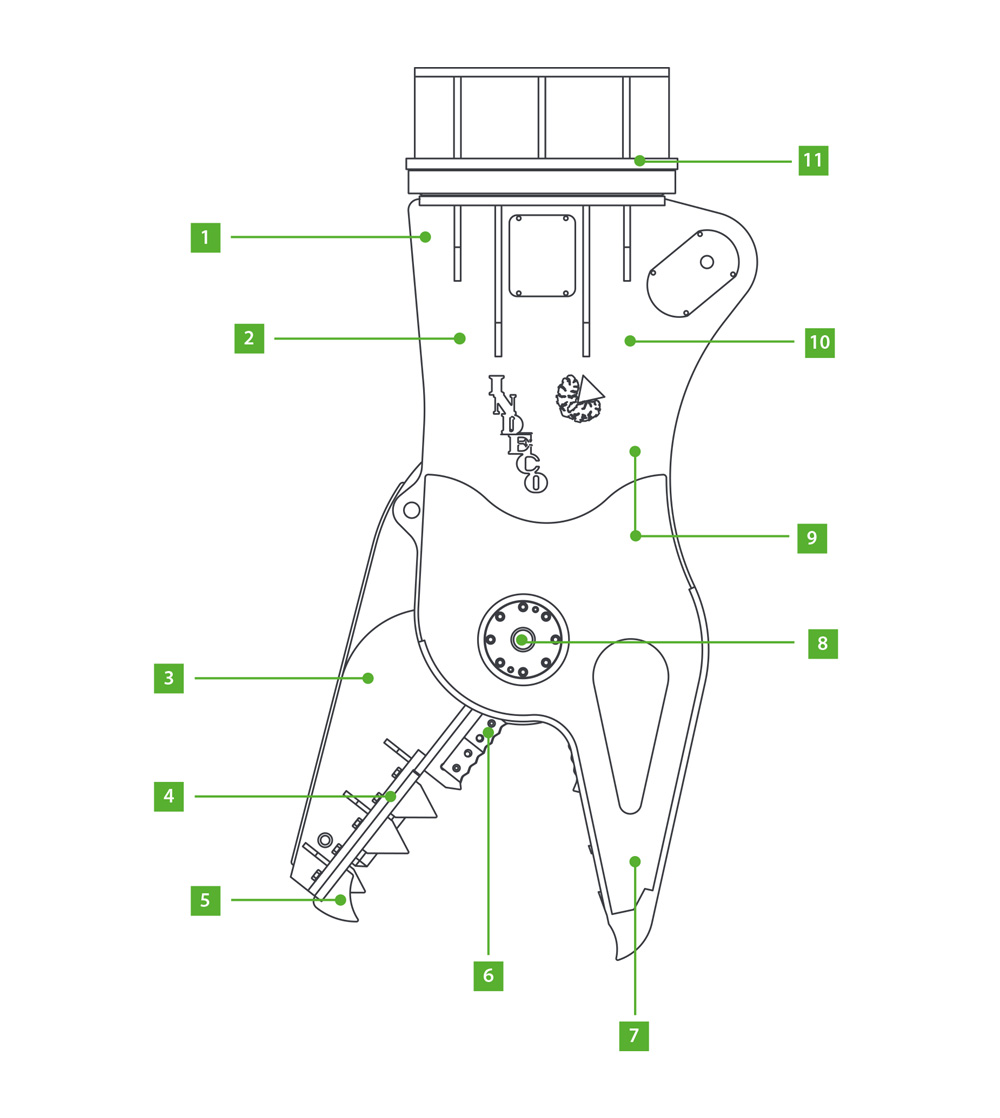

- 1 Position of hydraulic cylinder protects the rod.

- 2 Exclusive geometric design which ensures that the pulverizing force remains as constant as possible between maximum and minimum opening.

- 3 Wide opening between the jaws.

- 4 Special latches.

- 5 Interchangeable teeth mounted on a bolt-on plate with tooth sockets.

- 6 The distance between the cutters located inside the jaws can be adjusted, so that steel rods inside reinforced concrete can be cut more efficiently both sides of the interchangeable cutters can be used.

- 7 Innovative design provides better grip and improves manoeuvrability, extremely rigid structure prevents buckling.

- 8 Greasing system for better lubrication of moving mechanical parts.

- 9 Frame and jaws made with HARDOX©.

- 10 "Regeneration valve" which enables the movable jaw to be closed more quickly under no-load conditions.

- 11 Full 360° hydraulic rotation, with a protection valve, ensures that the material can be held firmly in the jaws and makes it easier to carry out demolitions in all conditions.

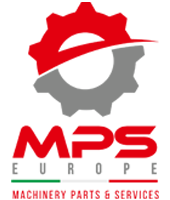

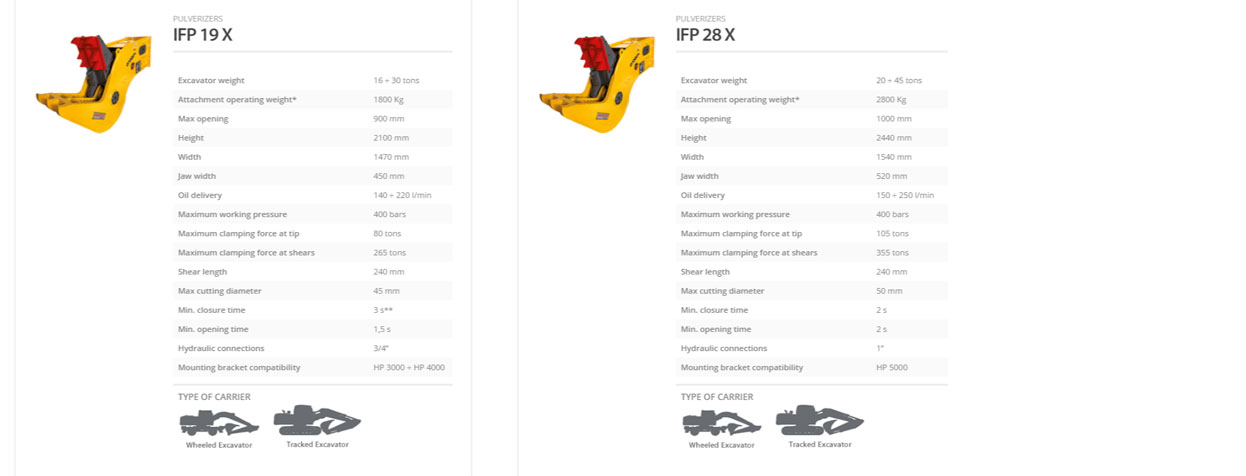

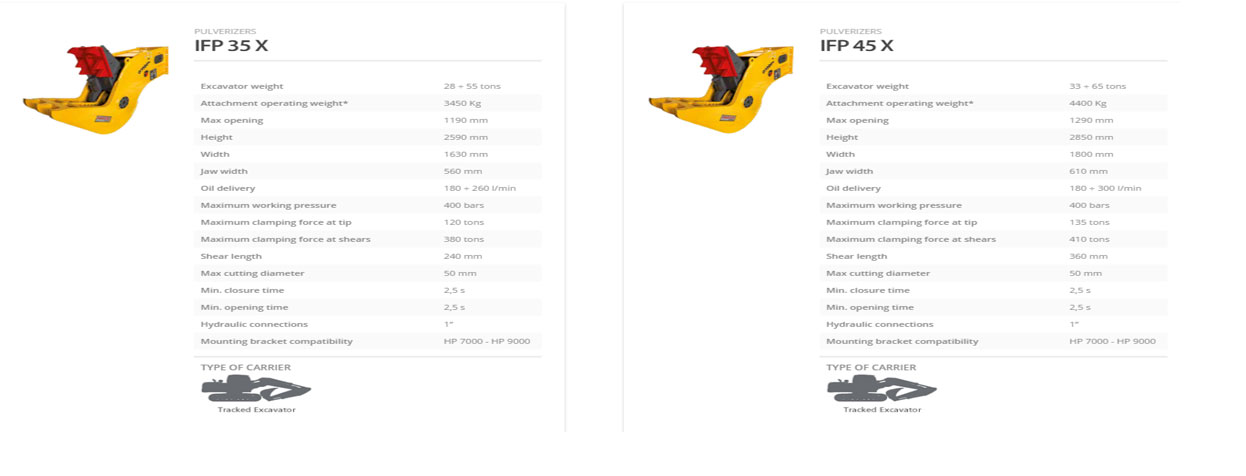

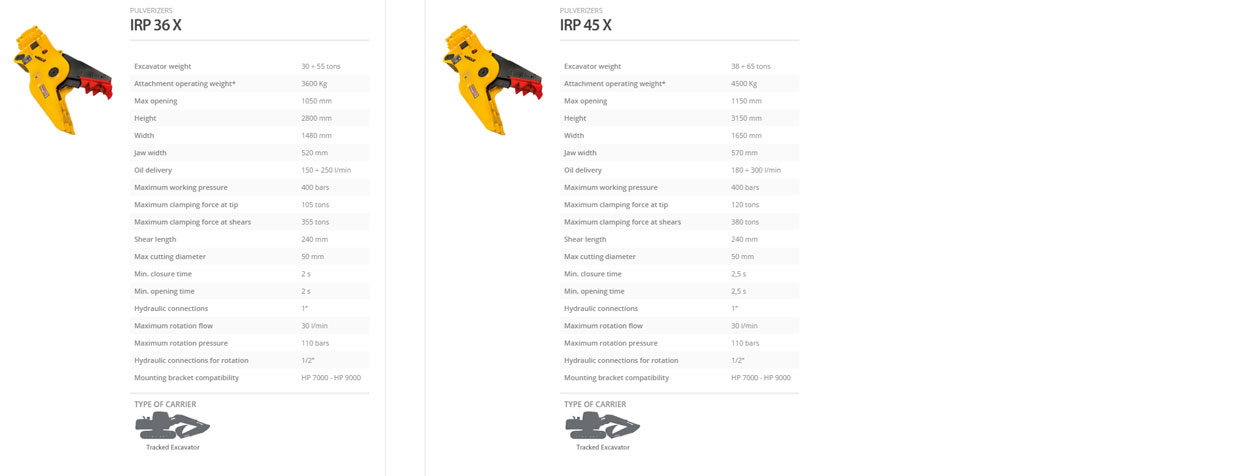

FULL RANGE

* The operating weight of the equipment includes mounting bracket compatible with Indeco construction standards. Any differences in weight may be due to a different mounting bracket configuration.

** without regeneration valve.

N.B. All illustrations and numerical data in this catalog are purely indicative and subject to change at our discretion and without notice.

We therefore reserve the right to modify them with a view to improving and continuously developing our product.