Boom Systems

IBS Series

Mounted over the mouth of a primary crusher, the boom system enables the breaker to reach into the mouth of the crusher, reducing oversized boulders as well as clearing any blockages in the hopper.

FEATURES

Initially manufactured and marketed by Indeco North America and Indeco Australia, the Indeco IBS Boom System soon had a strong impact on many other markets, having already proven to save time and money in many a quarry and mine, where it is used to reduce bridged and oversized material which could slow down crushing operations. Mounted over the mouth of a primary crusher, the boom system enables the breaker to reach into the mouth of the crusher, reducing oversized boulders as well as clearing any blockages in the hopper.Various remote-control systems enable the operator to manoeuvre the boom from the cabin. By doing so, plant down times can be safely eliminated. Our experience on the Australian and pan-American markets has enabled Indeco to develop a range of boom systems with outstanding reliability, ruggedness, productivity and profitability. Indeco IBS boom systems, made from extra-strength steel alloys, are tailor-made, and are designed according to the individual requirements and specifications set out by the customer.

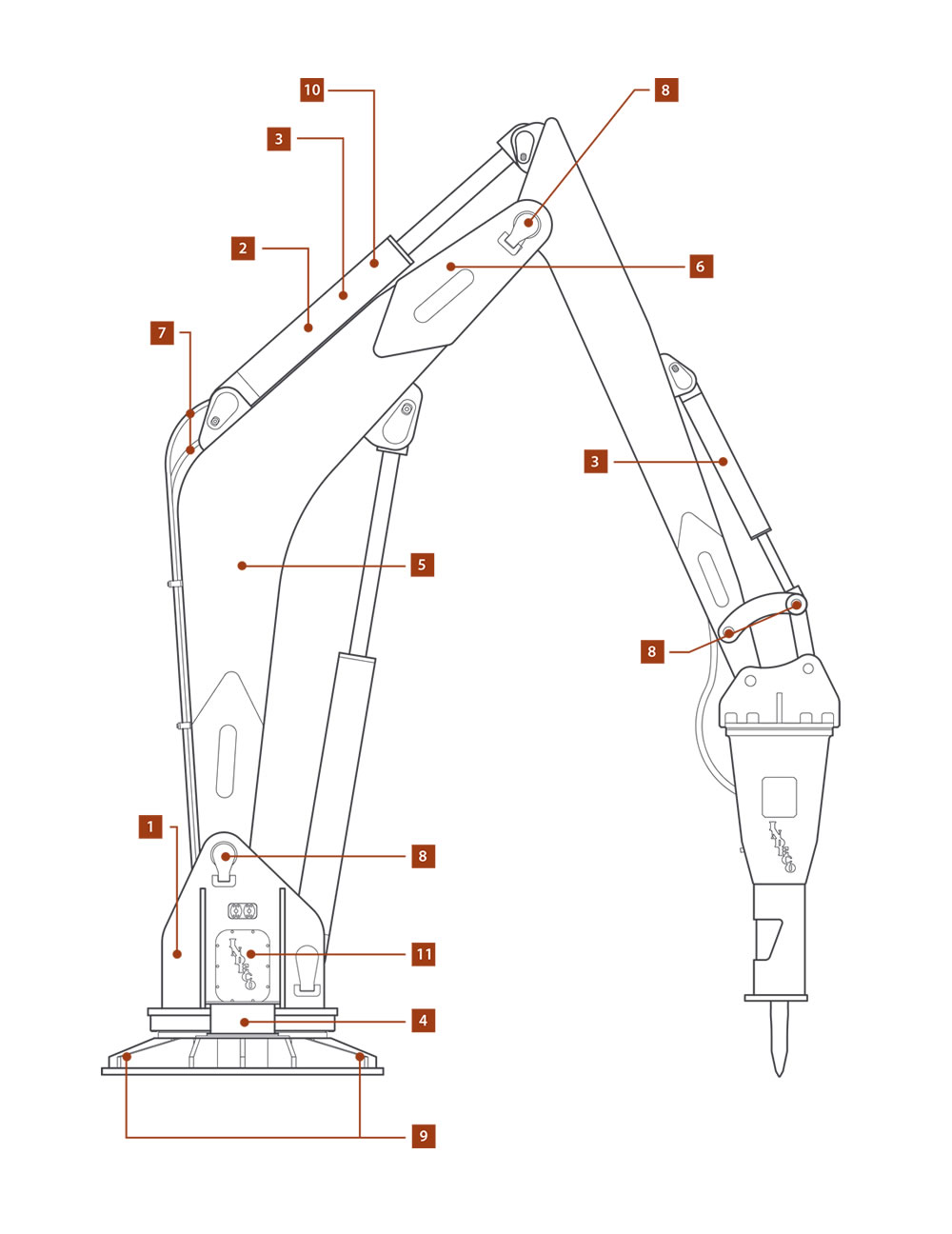

- 1 Electro-hydraulic proportional control valve..

- 2 Protected connections to cylinders..

- 3 Oversize long-stroke high-pressure cylinders.

- 4 High-pressure distributor for maximum rotation angle.

- 5 Variable-section high-strength steel frame.

- 6 Special torsion reinforcements.

- 7 High-pressure hydraulic hoses.

- 8 Heat treated and greased pins and bushing.

- 9 Oversized mounting base.

- 10 Anti-drop and load control valves.

- 11 Access panels for maintenance purposes.

ROTATION

Indeco IBS boom systems are available with three different types of rotation, for maximum flexibility, depending on the type of job they are used for.

360° slewing ring and hydraulic motor

360° rotation with a fifth wheel and pinion and planetary gear units for maximum operating flexibility makes the Indeco IBS similar to an excavator boom.

180° hydraulic actuator

true 180° rotation using a special hydraulic actuator designed and manufactured exclusively by Indeco, provides greater versatility and application in a wider work area.

150° side hydraulic pistons

150° rotation uses two oversize hydraulic pistons working in sequence, to ensure better performance and greater rotational power.

ACCESSORIES

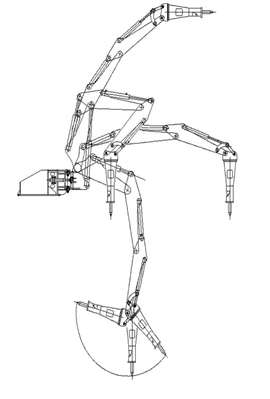

Three articulations

The Indeco hydraulic boom can be made with three articulations so as to increase the working area when the breaker is in a vertical position, to reach inaccessible positions under the mounting base, and to increase versatility of use.

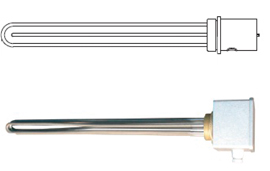

Oil warmer

At very low working temperatures and in cold climates, the oil warmer keeps the oil temperature constant.

Automatic greasing kit for boom and breaker

Optimises grease consumption, cutting out the machine down times once needed to lubricate moving parts. The kit includes a programmable pumping unit pack, hoses and breaker and boom fittings. The system increases the service life of all the ball bushings on the boom and in the moving parts of the breaker.

Oil level indicator

Indicator which warns the operator when the oil level is too low.

Control system

The Indeco IBS has a highly efficient control system with an electro-hydraulic proportional valve. Indeco has designed two different types:• remote control, with a special cable up to 90 m in length;

• wireless remote control for distances of up to 30 m.

Temperature indicator

Indicator which warns the operator when the temperature is too high.

Heat exchanger

High-efficiency radiator and auxiliary cooling fan to keep the oil temperature constant even in extreme operating conditions.

Hydraulic feed pump

There are three types of hydraulic feed pump: • gear pumps, for operating pressures of up to 200 bars;• axial piston pumps for operating pressures of over 200 bars;

• variable displacement pumps with load sensing.