MULTIPROCESSORIMP Series

Designed to ensure maximum versatility, the Indeco IMP multiprocessor is the perfect solution for specialist or non-specialist firms who need a tool that can handle a variety of different jobsite situations in the demolition and recycling field. Different jawsets enable it to be used in the various breaker, pulverizer and shear configurations on the same carrier.

IMP Series

Designed to ensure maximum versatility, the Indeco IMP multiprocessor is the perfect solution for specialist or non-specialist firms who need a tool that can handle a variety of different jobsite situations in the demolition and recycling field. Different jawsets enable it to be used in the various breaker, pulverizer and shear configurations on the same carrier.

FEATURES

Designed to ensure maximum versatility, the Indeco IMP multiprocessor is the perfect solution for specialist or non-specialist firms who need a tool that can handle a variety of different jobsite situations in the demolition and recycling field. Different jawsets enable it to be used in the various breaker, pulverizer and shear configurations on the same carrier.Made with the latest technologically advanced materials, such as special extra-strength HARDOXŽ steel alloys, which eliminates any flexing of the body, the Indeco IMP multiprocessor is designed to withstand high levels of pressure, wear and abrasion, and prolonged use regardless of jobsite conditions. Unique features such as the special design of the jaws, the tried and tested rotation mechanism (found on all Indeco rotating products) and interchangeable teeth on the mobile jaw in pulverizer configuration, help this product perform very well in all applications.

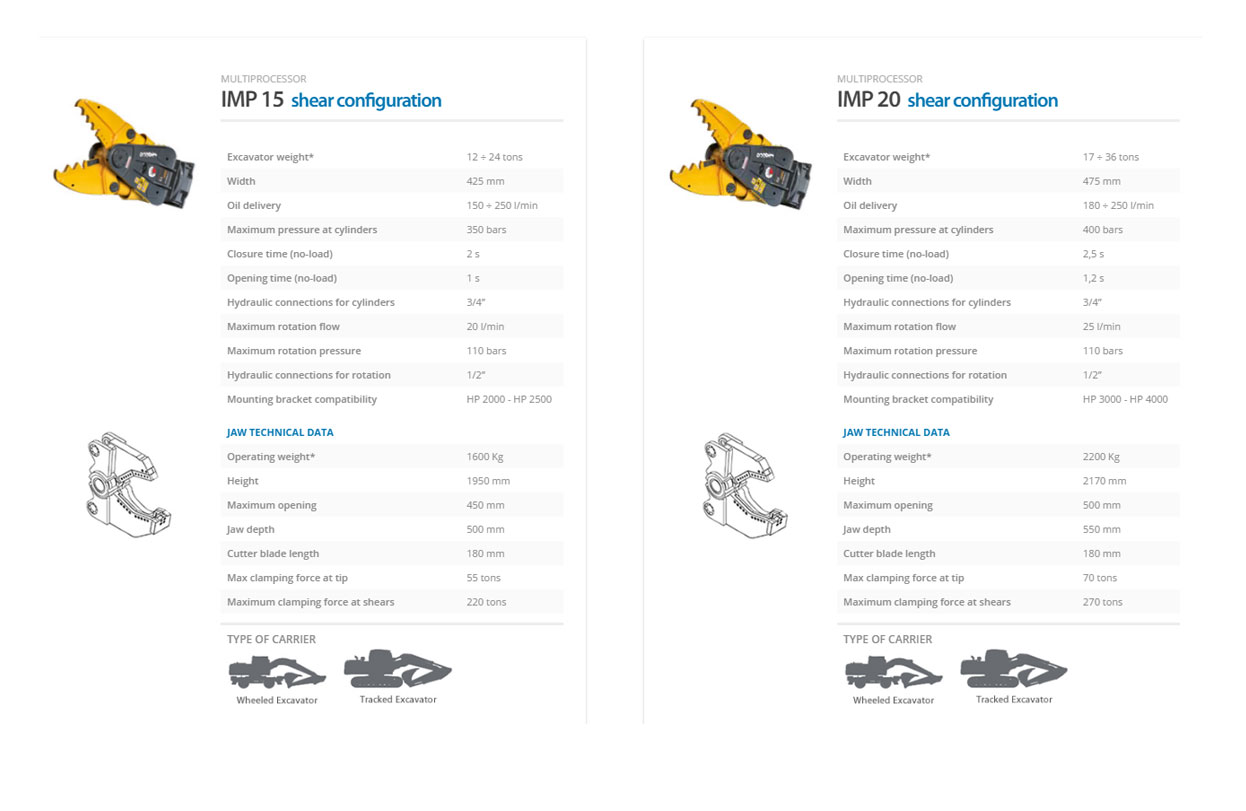

In “shear” configuration, some of the unique features of the Indeco ISS shears have been incorporated, such as the cutting geometries, the blade configurations, and the exclusive piercing system.

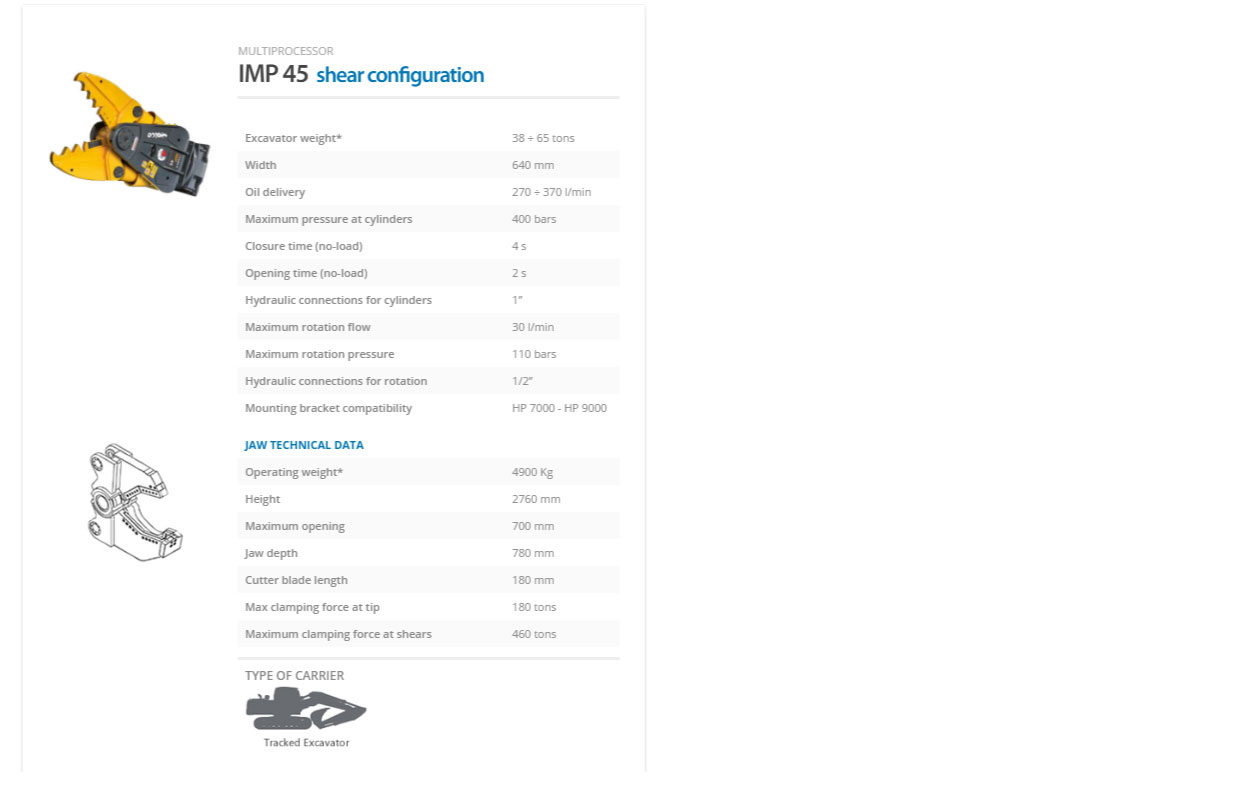

- 1 Full 360° hydraulic rotation, with a protection valve, makes it easier to carry out demolitions in all conditions, and ensures that the material can be held firmly in the jaws.

- 2 Steel shafts protecting the piston rods against accidental on-site damage.

- 3 Three different jaw sets for demolition, pulverizing and cutting.

- 4 Both sides of the interchangeable cutters can be used, thus doubling usage time

- 5 Single axis of rotation for quicker and more efficient maintenance and jaw set replacement;

Greasing system for improved lubrication of moving mechanical parts. - 6 Two large pistons providing dynamic but balanced demolition power.

- 7 Innovative design and robust housing.

- 8 Frame and jaws made with HARDOX©.

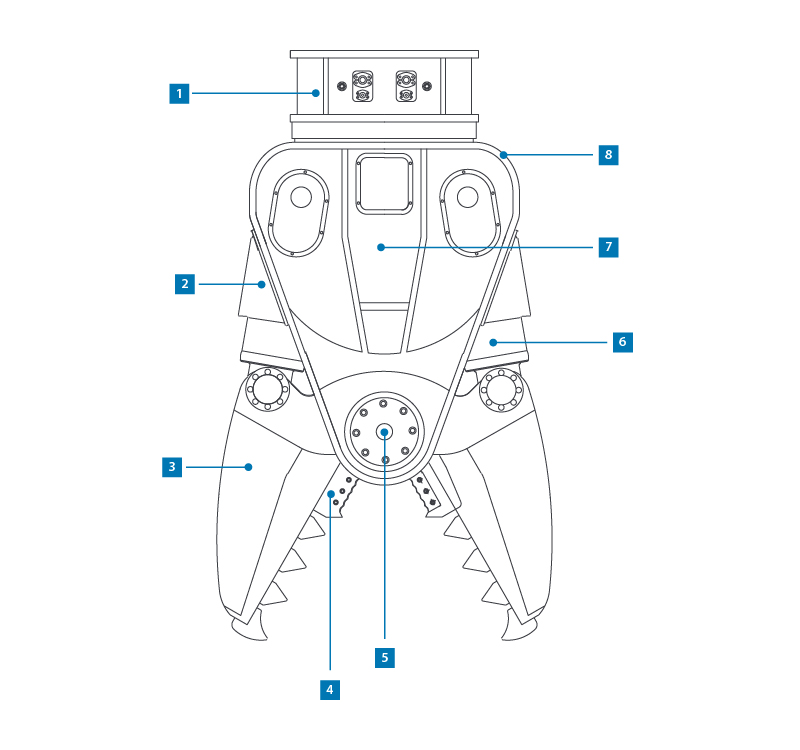

- 1 The distance between the interchangeable cutters can be adjusted, so that steel rods inside reinforced concrete can be cut more efficiently.

- 2 Theets in special heat-treated steel.

- 3 The distance between the interchangeable cutters can be adjusted, so that steel rods inside reinforced concrete can be cut more efficiently.

- 4 Interchangeable theet mounted on a bolt-on plate with tooth sockets.

- 5 Four special steel blades: all the same size, reversible and interchangeable so that all of the cutting edges can be used.

- 6 Exclusive dual-profile piercing tip system in both upper and lower tips, for a clean gradual cut.

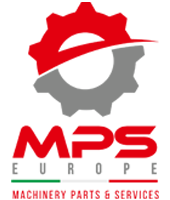

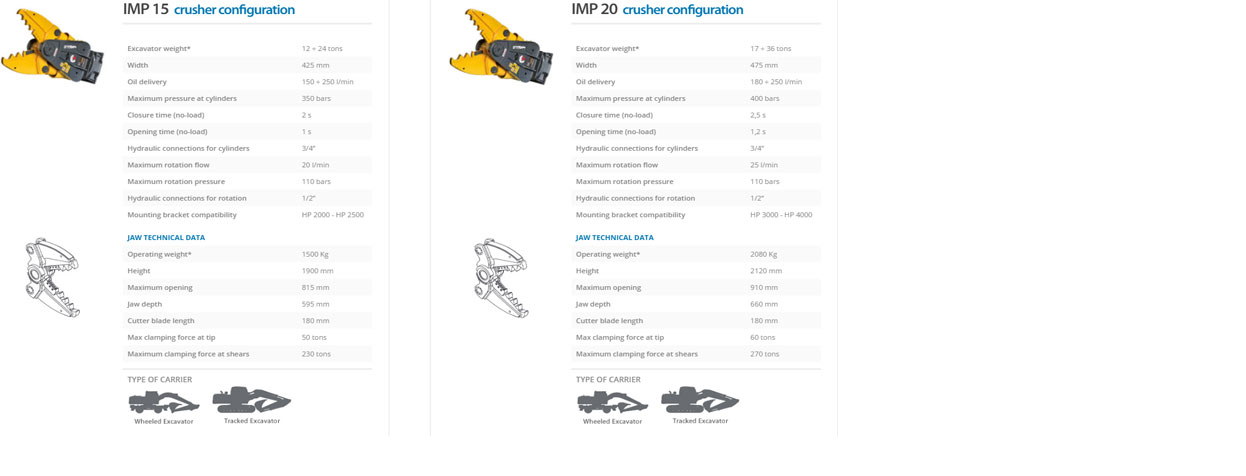

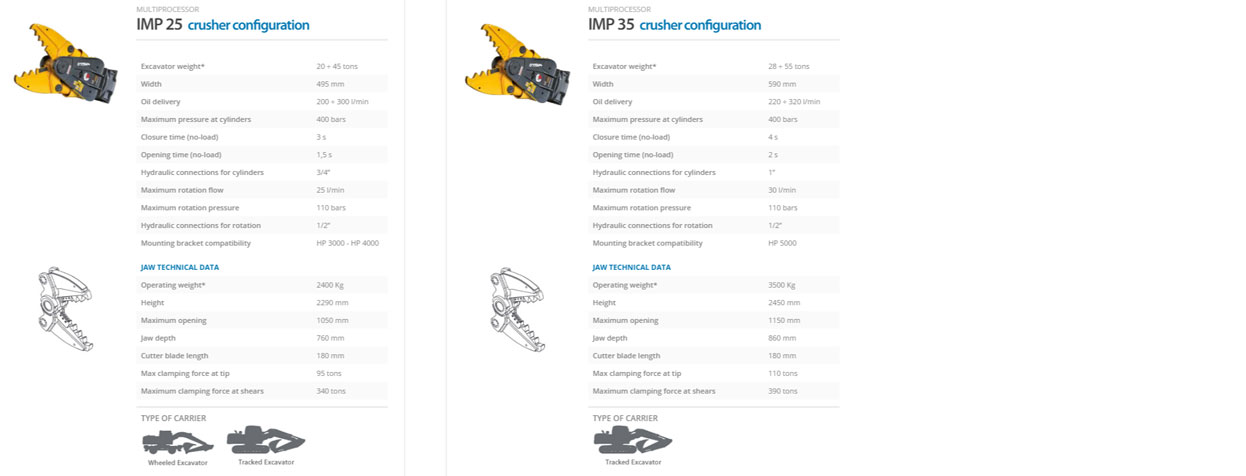

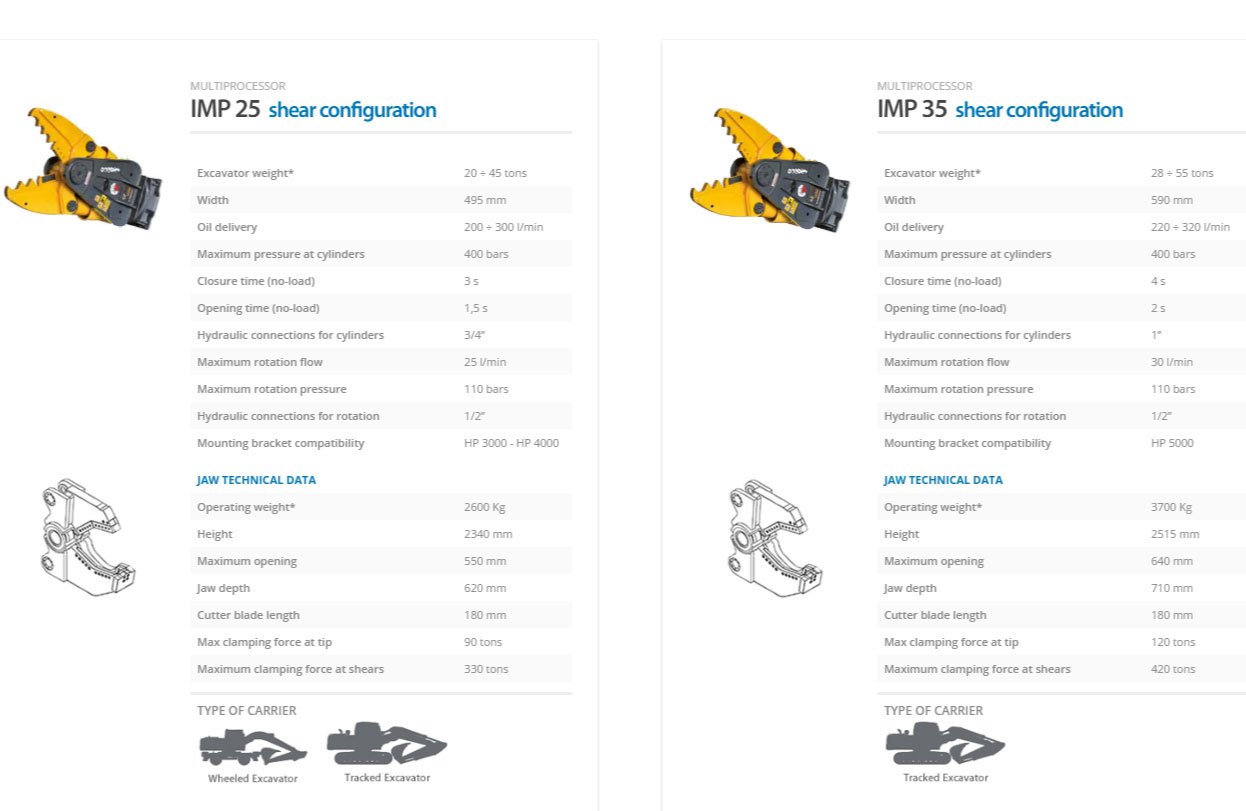

FULL RANGE

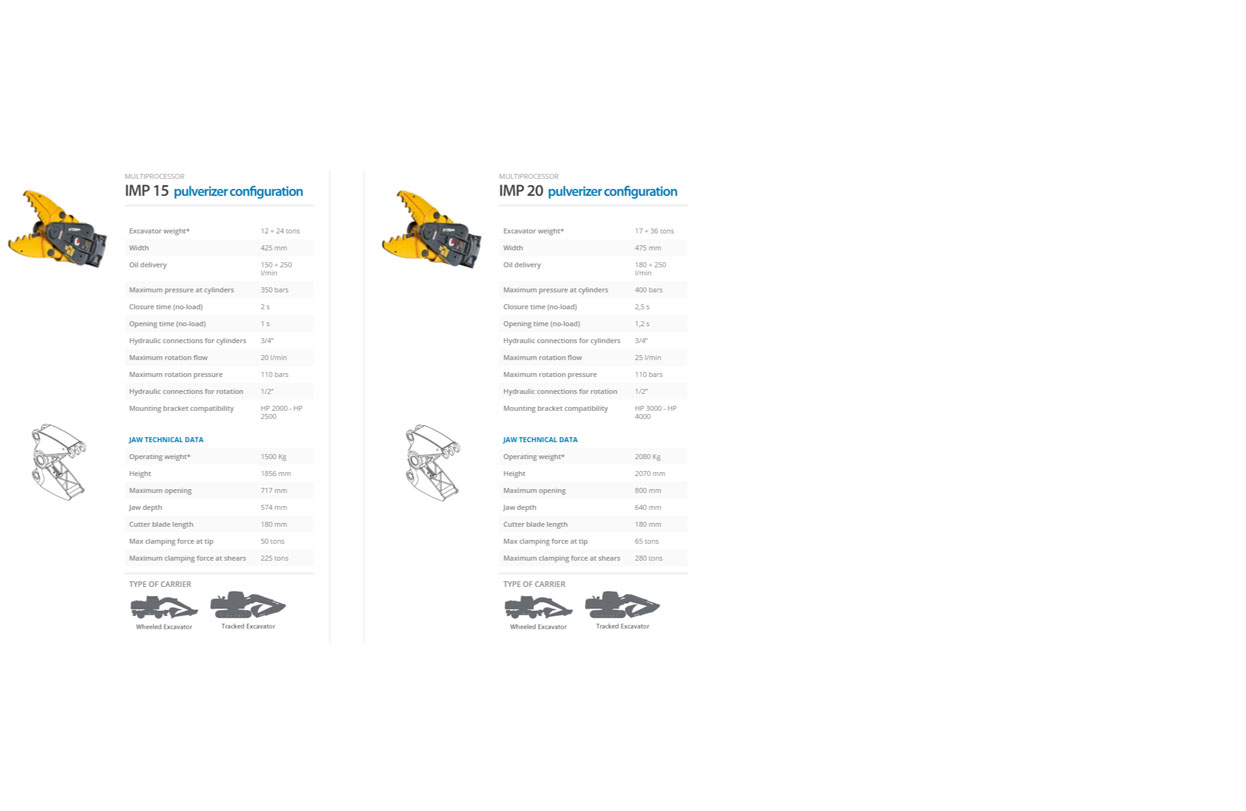

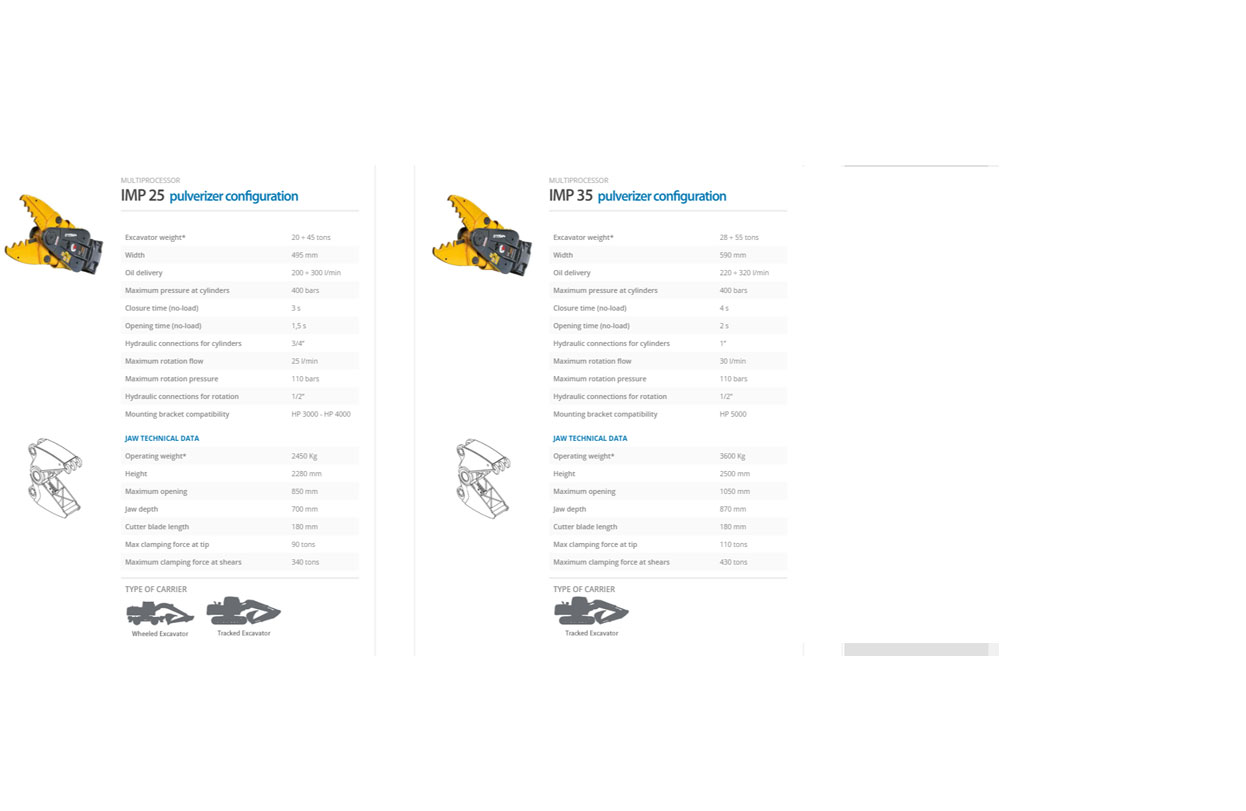

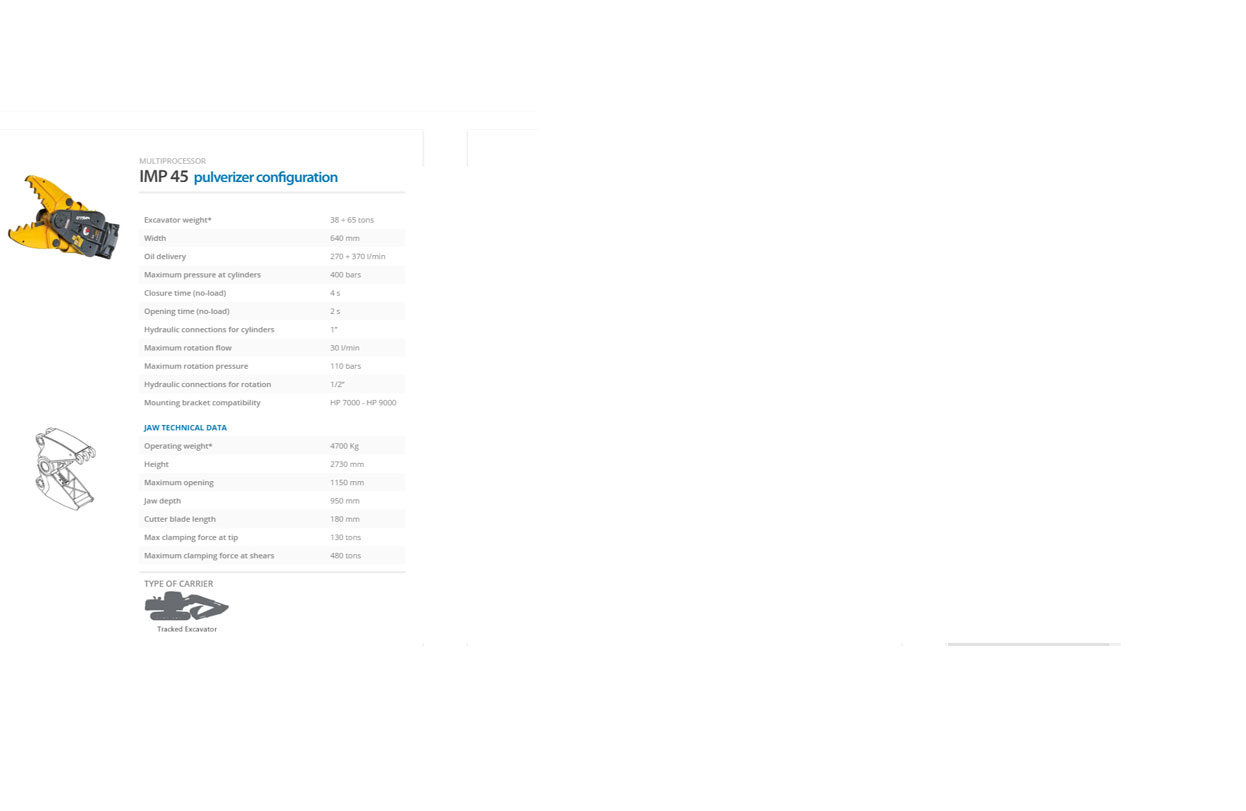

* The operating weight of the equipment includes mounting bracket compatible with Indeco construction standards. Any differences in weight may be due to a different mounting bracket configuration.

N.B. All illustrations and numerical data in this catalog are purely indicative and subject to change at our discretion and without notice.

We therefore reserve the right to modify them with a view to improving and continuously developing our product..