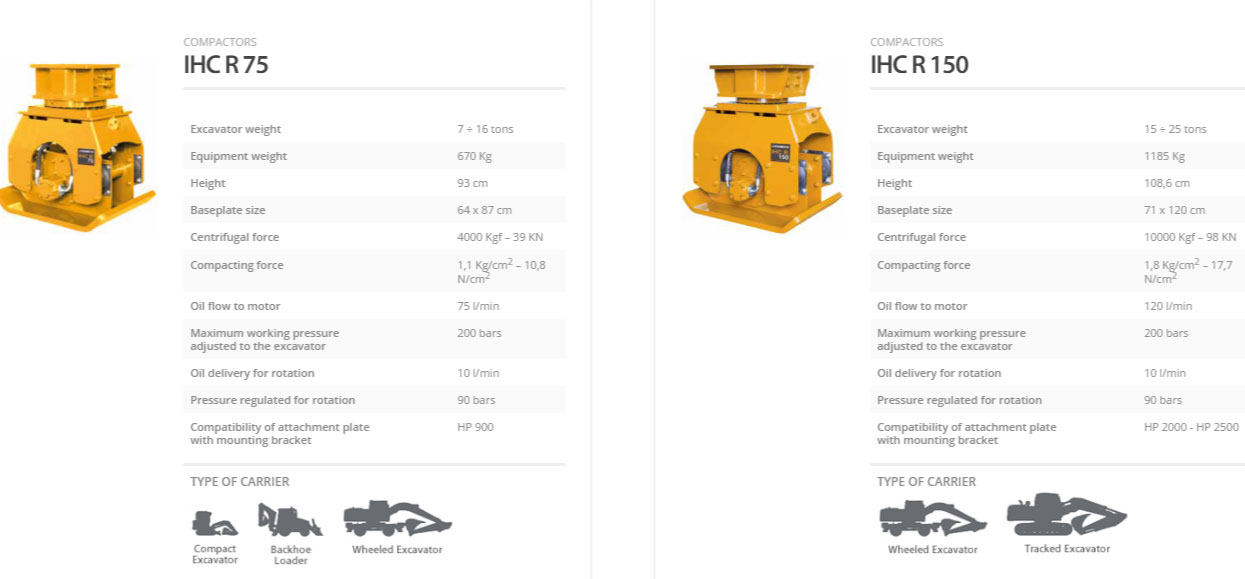

COMPACTORSIHC and IHC R Series

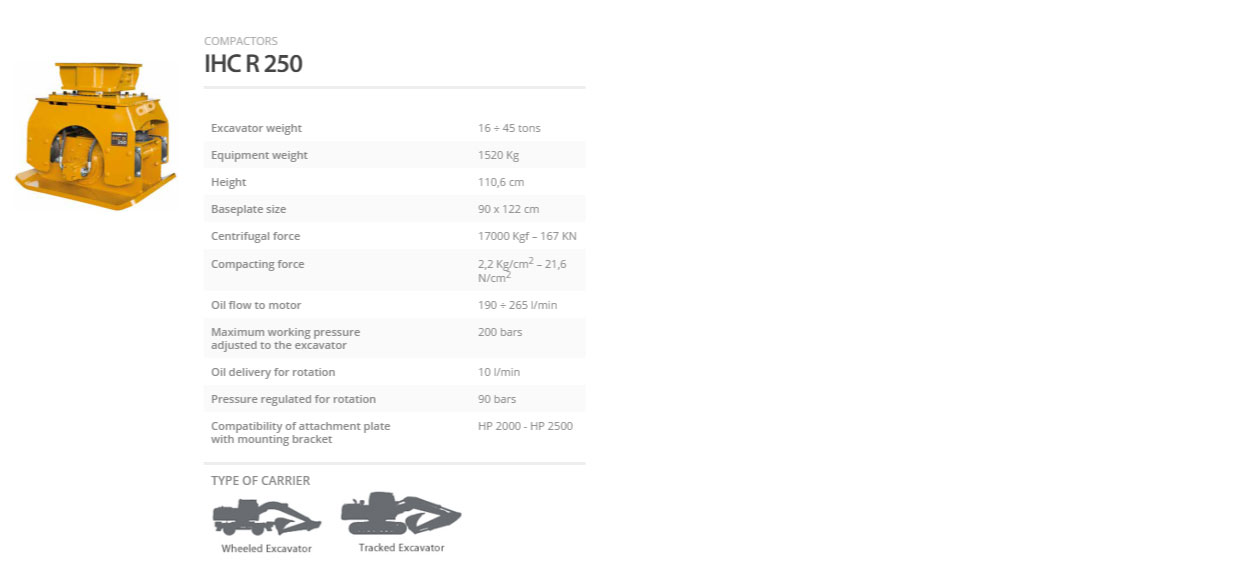

Indeco's fixed or rotating IHC hydraulic compactors offer superior efficiency and versatility compared with other products on the market. Being fitted with the same mounting bracket as other Indeco hydraulic equipment makes it easy to switch from one tool to another at the jobsite.

IHC and IHC R Series

Indeco's fixed or rotating IHC hydraulic compactors offer superior efficiency and versatility compared with other products on the market. Being fitted with the same mounting bracket as other Indeco hydraulic equipment makes it easy to switch from one tool to another at the jobsite.

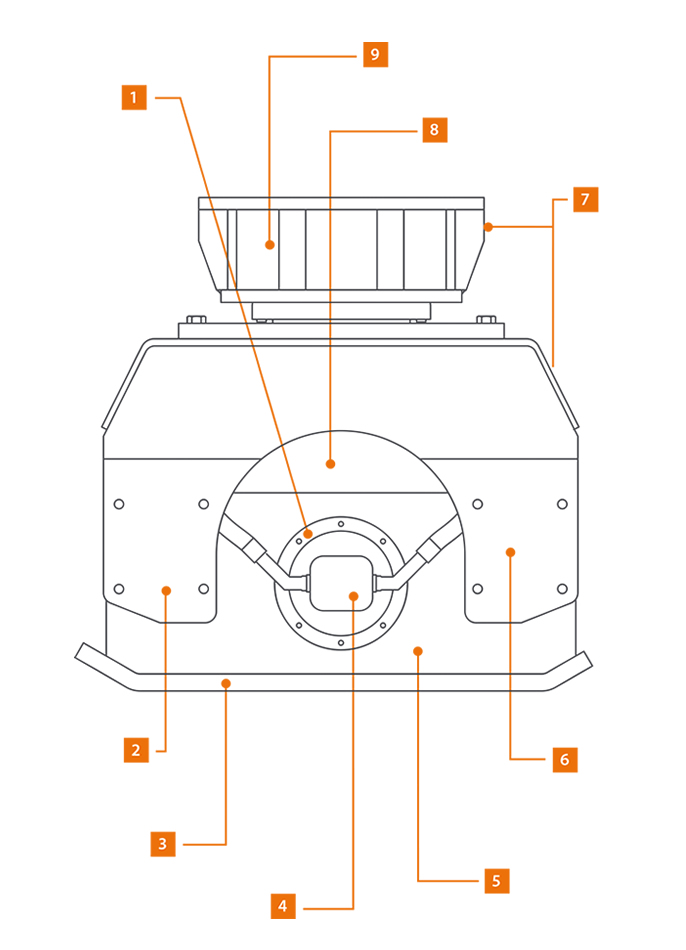

FEATURES

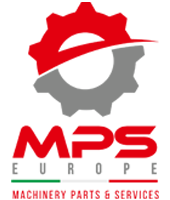

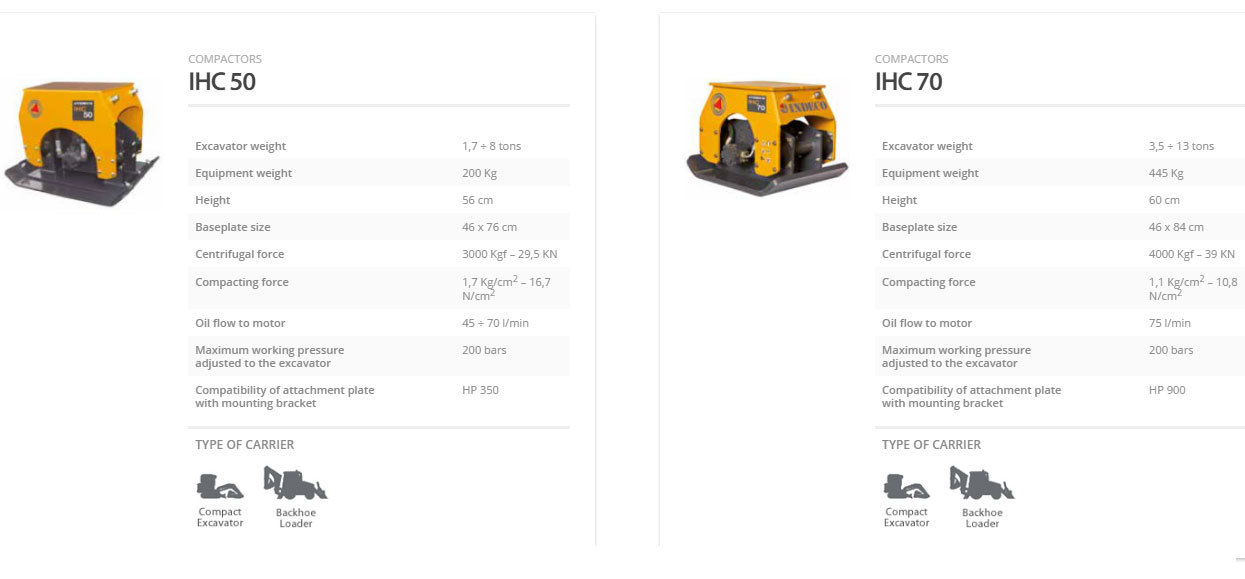

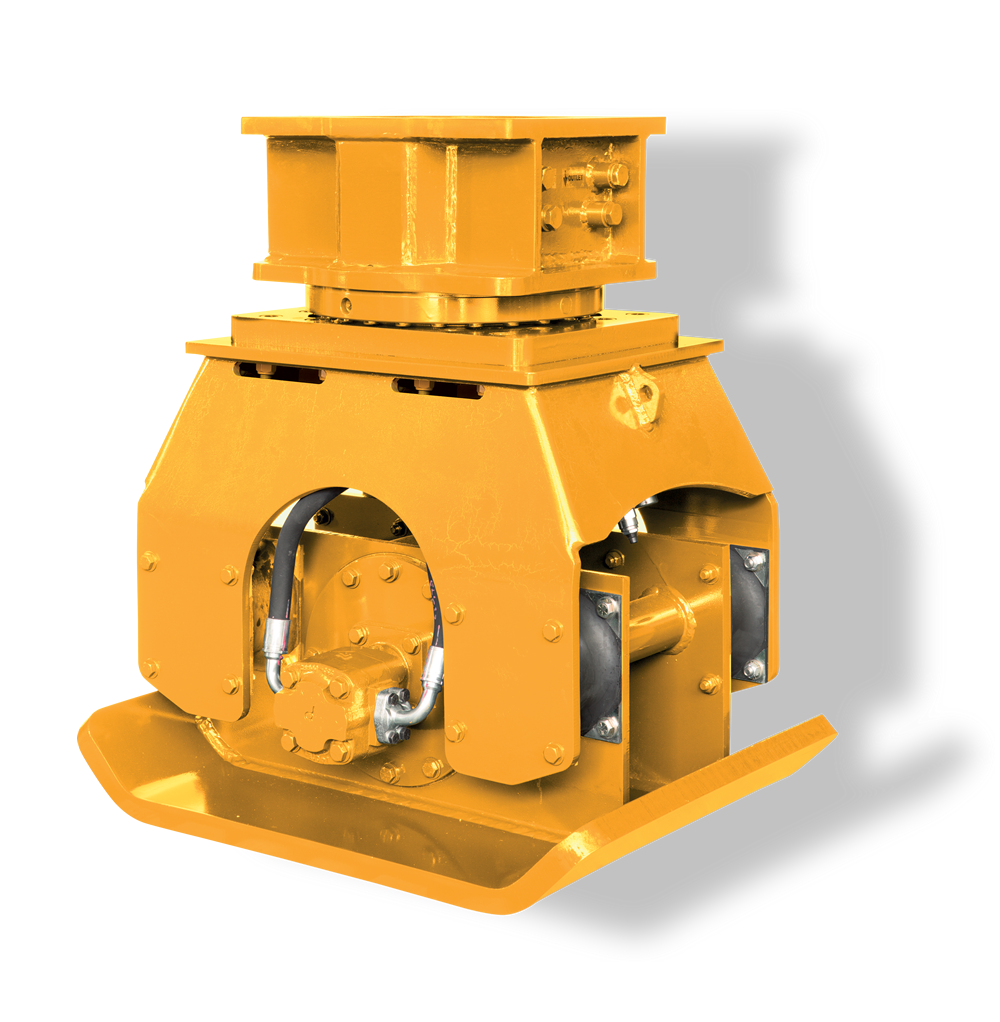

Indeco IHC compactors combine high compaction 9 with fast turnaround times. They are a very efficient replacement both for traditional risky and tiring manual equipment and for self-propelled rollers, which are at great risk of rollover during slope applications. Compaction is achieved by applying both the dynamic force of a hydraulically-driven vibration system and the static weight of the carrier boom to the thick steel baseplate of the compactor.Of course, the dynamic forces have to be powerful enough to vibrate the steel baseplate. To enable this to happen, Indeco compactors (mounted straight onto the carrier boom) are hydraulically driven with an oil-bath bearing system, which gives a balanced design of compaction force and vibration speed, so as to achieve the depth penetration needed to reduce air voids and move more material faster. Indeco’s fixed or rotating IHC hydraulic compactors offer superior efficiency and versatility compared with other products on the market. Being fitted with the same mounting bracket as other Indeco hydraulic equipment makes it easy to switch from one tool to another at the jobsite.

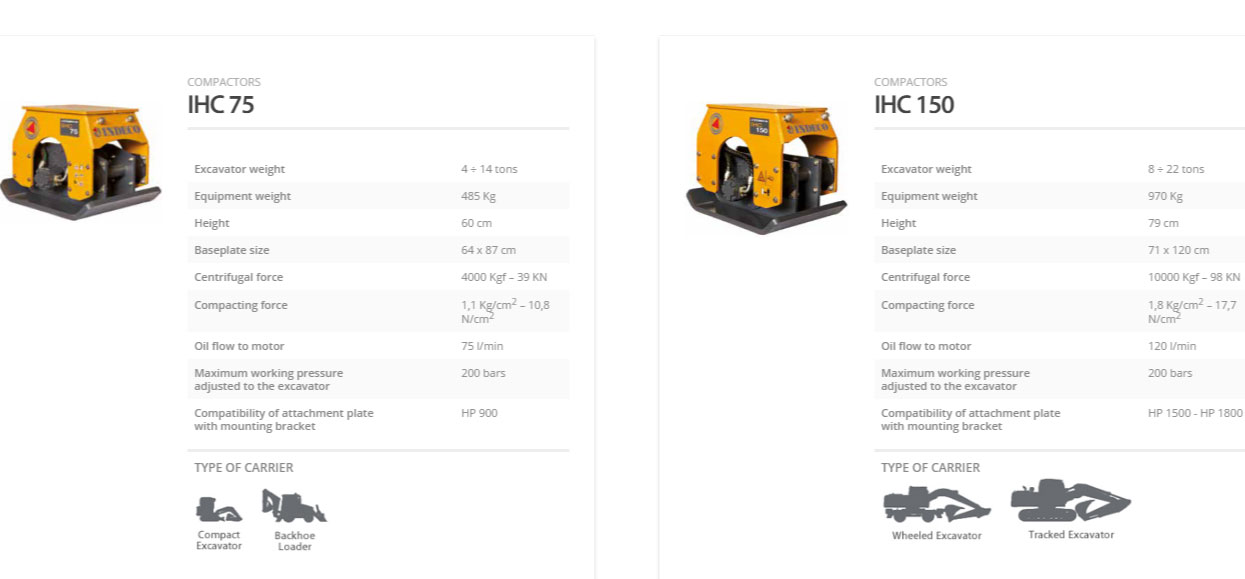

Using just the carrier’s hydraulic circuit, they are ideal for compacting backfill for trenches, as well as embankments or other steep slope applications, around foundations or close to other obstacles. Perfect for working on grainy, cohesive and semi-cohesive soils, optional adapters on the vibratory plate turn them into highly efficient pile-driving tools. Indeco’s rotating compaction plate, the IHC R, makes it much easier to position the excavator at the right angle to the working surface, especially for jobs in narrow pipe trenches and confined areas, where the compaction plate needs to reach into difficult corners or skirt round manholes and other obstacles.

- 1 System with roller bearings and oil-bath lubrication.

- 2 Rubber shock-absorption system.

- 3 Thick chassis and baseplates made from special steel alloys.

- 4 Hydraulic system.

- 5 Innovative design.

- 6 Pressure- and flow-control valve.

- 7 Intelligent hydraulic connections.

- 8 Hydraulic motor with special seals.

- 9 Full 360° hydraulic rotation, with protection valve.

FULL RANGE

* The operating weight of the equipment includes mounting bracket compatible with Indeco construction standards. Any differences in weight may be due to a different mounting bracket configuration.

N.B. All illustrations and numerical data in this catalog are purely indicative and subject to change at our discretion and without notice.

We therefore reserve the right to modify them with a view to improving and continuously developing our product.

ACCESSORIES

Backfill blade

A useful optional, mounted on the compactor, for smoothing and levelling the earth to be compacted, without needing to switch from compactor to bucket.